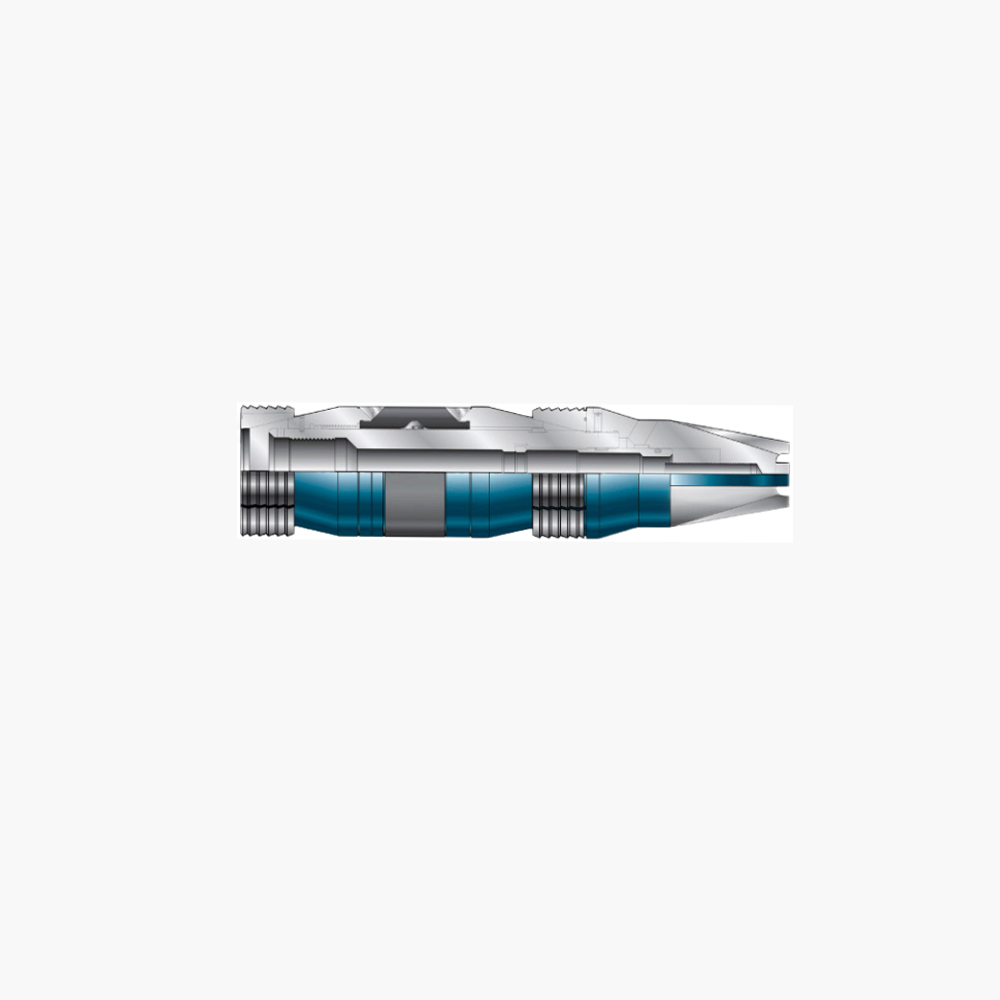

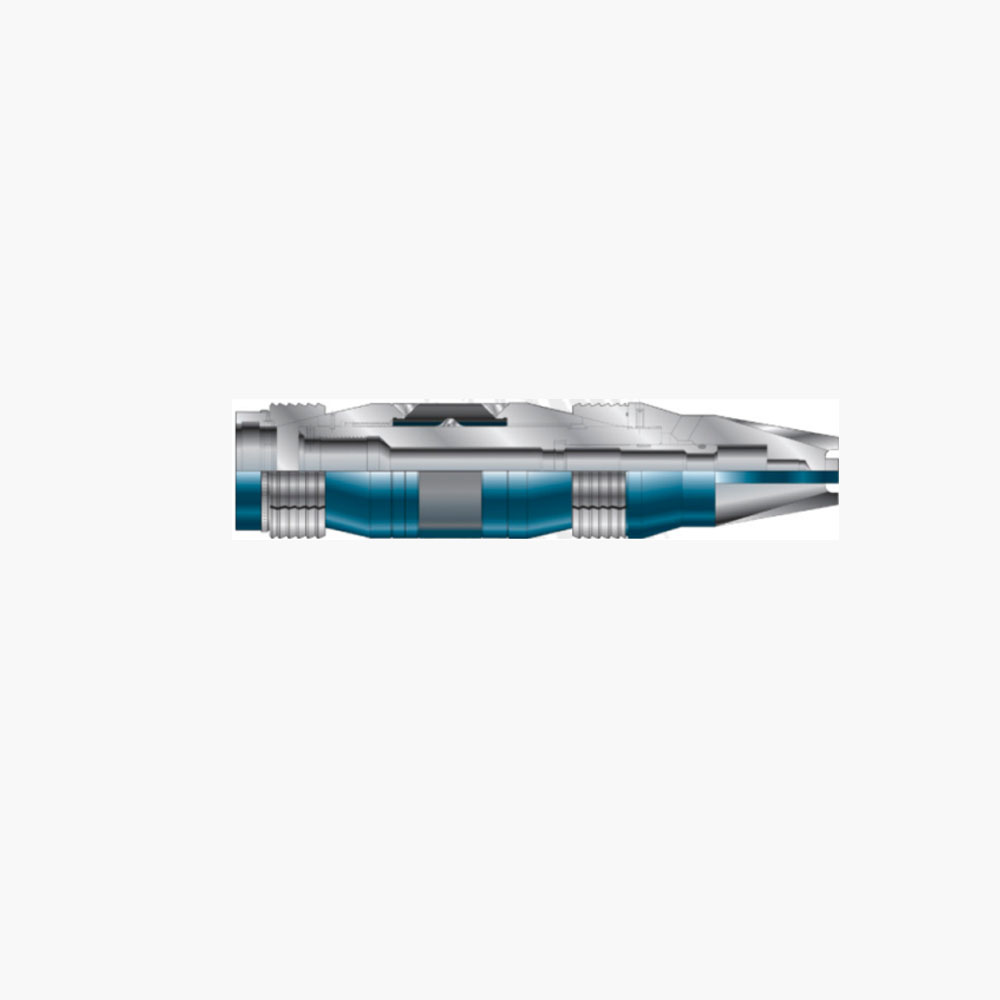

The SHMB bridge plug can be used for temporary and permanent sealing of oil, gas and water layers. Specifically, it can be used in production well sealing channeling, water plugging, fracturing, acidizing and other construction. The SHMB bridge plug requires no special seat sealing tools, and has a compact structure and small outside diameter. After the bridge plug seat is sealed, cement can be squeezed directly on the bridge plug.

Specifications

| PN# | Casing OD | Casing Wt | Tool OD | Release Force |

| (in) | (lbs/ft) | (in) | (lbs) | |

| D22-0450-303 | 4 1/2 | 9.5-16.6 | 3.59 | 33,000 |

| D22-0500-303 | 5 | 11.5-20.8 | 3.93 | |

| D22-0550-303 | 5 1/2 | 13-23 | 4.31 | |

| D22-0575-303 | 5 3/4 | 14-25.2 | 4.7 | |

| D22-0662-303 | 6 5/8 | 17-32 | 5.37 | 50,000 |

| D22-0700-303 | 7 | 23-35 | 5.68 | |

| D22-0701-303 | 7 | 17-23 | 6.00 | |

| D22-0762-303 | 7 5/8 | 20-39 | 6.31 | |

| D22-0862-303 | 8 5/8 | 24-49 | 7.12 | |

| D22-0962-303 | 9 5/8 | 29.3-58.5 | 8.12 | |

| D22-1075-303 | 10 3/4 | 32.7-60.7 | 9.43 | |

| D22-1176-303 | 11 3/4 | 38-60 | 10.43 | |

| D22-1337-303 | 13 3/8 | 48-84.5 | 11.88 | |

| D22-1600-303 | 16 | 65-118 | 14.12 | |

| D22-2000-303 | 20 | 94-133 | 18.37 |

The SHMB bridge plug is suitable for casing sizes from 4 1/2 “to 20”.

Features:

- Simple and compact structure

- No special seat sealing tools, directly throw the ball to suppress and then lift the seat seal

- You can release right hand in case of emergency

- Integrated rubber cylinder and smooth metal back ring form a reliable sealing system

- Can withstand high pressure, 7 “and below specifications can withstand up to 70MPa(10000psi) pressure difference

- The recommended use temperature of conventional rubber sleeve is 148 ° C (300 ° F), and can provide a maximum of 204 ° C (400 ° F) rubber cylinder