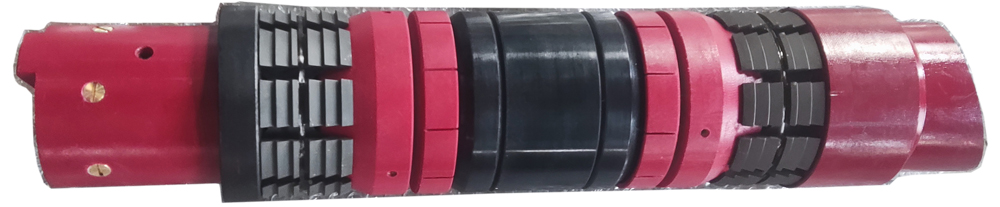

Composite bridge plugs are mainly used for temporary plugging of oil and gas wells and for fracturing construction.

Principle

The composite bridge plug uses the relative force generated by the setting tool (cable or oil pipe to transmit hydraulic pressure) to act on the lower joint, exerting a compressive force on the sealant barrel through the cone. Within a certain tension range, the bridge plug slips rupture and Embedded on the inner wall of the casing, the rubber barrel expands and seals, completing the setting. When the tension continues to rise and reaches a certain value, the shear nails are broken and the setting tool is separated from the bridge plug. This process is completed; after the setting tool is taken out, construction operations such as fracturing can be carried out. After the operation is completed, the composite bridge plug can be Quickly drill out according to later measures and production needs.

Features

- Suitable for sealing bottom water in 5 1/2″ &7“ casing wells and selecting layers for fracturing.

- The sealing tool and the bridge plug are designed as separate parts. Except for slips, the rest of the sealing parts are made of composite materials.

- After reaching the predetermined position, pitch the ball, hydraulic setting, and two-way slip anchoring.

- The pipe string is removed by ordinary grinding and milling. The drilling time for a single bridge plug is less than 1 hour, and the multi-stage bridge plug has an anti-rotation slope when drilling out.

- Equipped with a resistance mechanism, it is better to avoid setting in case of obstruction or long-term oil pipeline transmission.

- Custom O.D. plugs are available upon request.