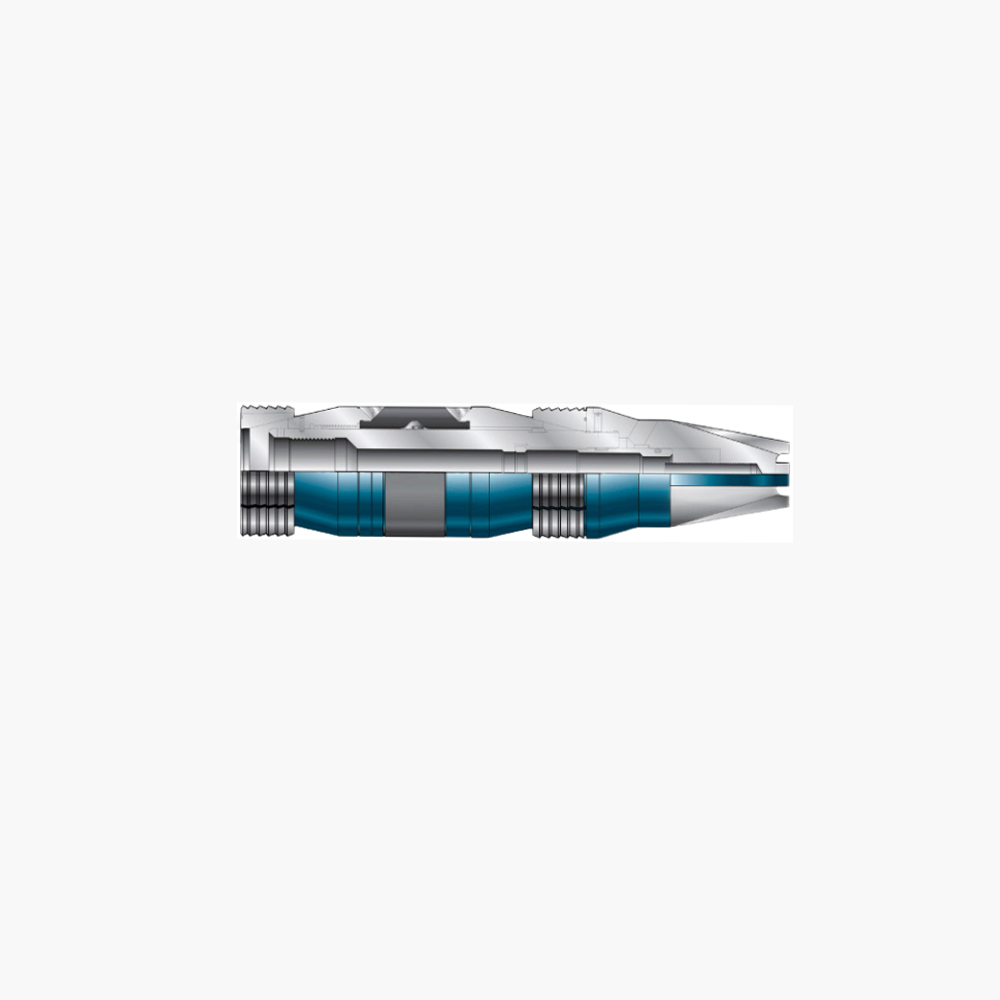

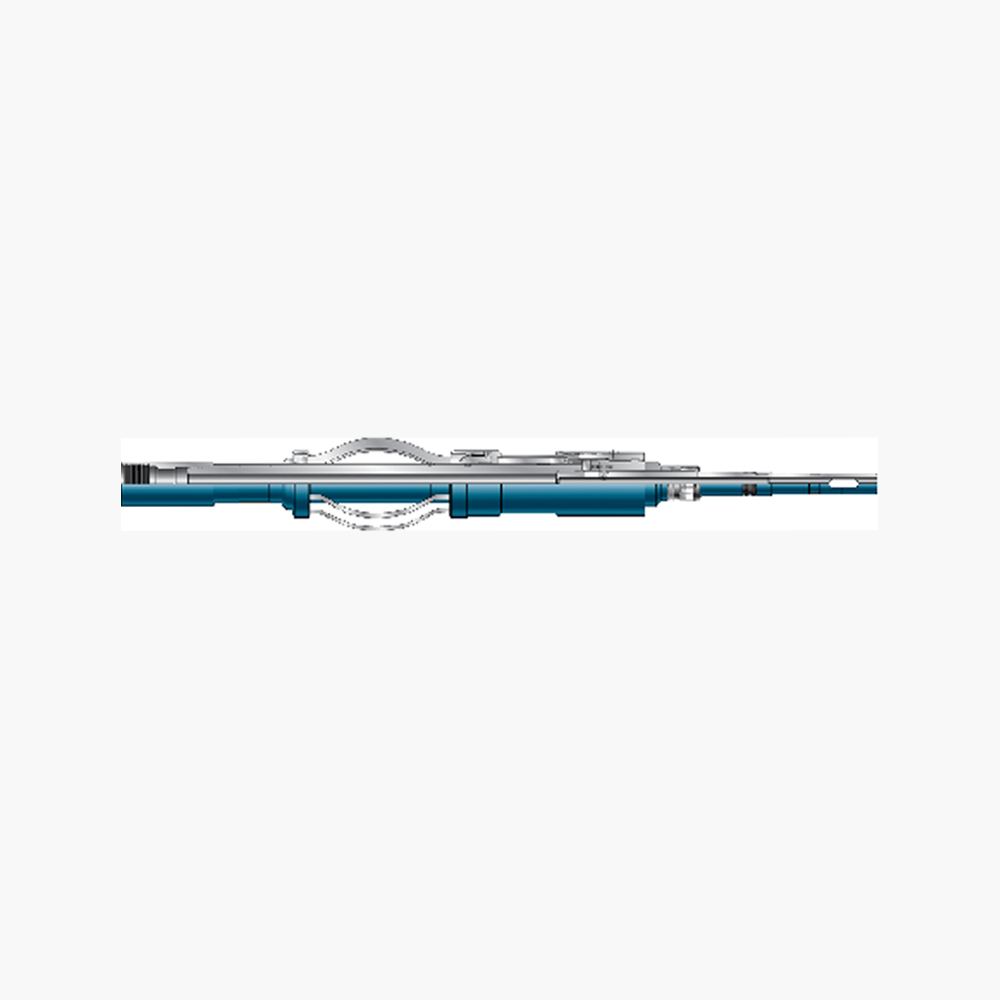

MWR type cement retainer has compact structure, small outside diameter and is easy to drill. Suitable for a variety of casing specifications. Ratchet lock ring structure maintains the setting load. The integral cartridge and smooth metal back ring form a reliable sealing system. Integral slips avoid mid-setting and are easy to drill out.

Specifications

| PN# | Casing OD | Casing Wt | Tool OD | Setting Tool | Setting Kits | Seal Nipple |

| (in) | (lbs/ft) | (in) | ||||

| D22-0450-001 | 4 1/2 | 9.5-16.6 | 3.59 | #10 | D22-0450-102 | D22-0450-010 D22-0450-012 |

| D22-0500-001 | 5 | 11.5-20.8 | 3.93 | #20 | D22-0500-101 | |

| D22-0550-001 | 5 1/2 | 13-23 | 4.31 | D22-0550-102 | ||

| D22-0575-001 | 5 3/4 | 14-26 | 4.7 | D22-0575-101 | ||

| D22-0662-001 | 6 5/8 | 17-32 | 5.37 | D22-0662-101 | D22-0700-010 D22-0700-012 | |

| D22-0700-001 | 7 | 17-35 | 5.68 | D22-0700-152 | ||

| D22-0762-001 | 7 5/8 | 20-39 | 6.31 | D22-0762-101 | ||

| D22-0862-001 | 8 5/8 | 24-49 | 7.12 | D22-0862-101 | ||

| D22-0962-001 | 9 5/8 | 29.3-58.4 | 8.12 | D22-0962-103 | ||

| D22-1075-001 | 10 3/4 | 32.75-60.7 | 9.43 | D22-1075-101 | ||

| D22-1176-001 | 11 3/4 | 38-60 | 10.43 | D22-1176-101 | ||

| D22-1175-001 | 11 3/4 | 60-83 | 9.94 | D22-1175-101 | ||

| D22-1337-001 | 13 3/8 | 48-80.7 | 11.88 | D22-1337-101 | ||

| D22-1600-001 | 16 | 65-118 | 14.12 | D22-1600-101 | ||

| D22-2000-001 | 20 | 94-133 | 18.37 | D22-2000-101 |

MWR cement retainers are suitable for casing from 4 1/2 “to 20” for secondary squeeze operations.

Features

- Can be set directly with MWSB type cable setting tool or MHSB type hydraulic setting tool;

- Can be milled and drilled;

- The ratchet lock ring maintains the setting load to ensure safe setting under pressure changes;

- Integral rubber cylinder and smooth metal back ring form a reliable sealing system;

- Can withstand high pressure, 7 “and below specifications can withstand up to 70MPa(10000psi) pressure difference;

- The recommended temperature for conventional rubber sleeve is within 148 ° C (300F). Please consult online customer service for other working conditions.